Sustainability in Print.

At VGL we are aware of the impact the printing industry can have on the environment. We recognise the importance of being responsible in terms of the suppliers and materials we choose to work with, the procedures in our printing facilities and where our printed graphics end up at end of life.

Although there is always more to be done, we continually strive to improve. At VGL we use science and technology to help us continue to be a leading supplier of environmentally friendly and sustainable print solutions.

Environmental Management System.

Built on confidence.

Inherent in our manufacturing practices is compliance with BSI ISO 14001 for Environmental Management, an accreditation that has been retained by VGL since 2011.

We take a full product life cycle approach, working with our suppliers and customers, consistently adjusting our products, technology, and operational processes to reduce the environmental impact of our activities - Reduce, Re-use, Recycle and Recover where possible.

A Strategic Waste Hierarchy.

Reduce, Re-use, Recycle and Recover.

We are committed to a circular economy and look to adopt processes that enable existing materials to be repurposed at the end of their use.

The MetaStream™ process, for example, enables a range of vinyl, overlam or paper to be transformed into notepads, plastic chairs or bollards, ensuring a second lease of life.

Sustainable Materials.

Pushing the boundaries in print.

As well as giving our printed materials an opportunity to be repurposed further, we continually explore new materials manufactured by our suppliers and partners that offer a more sustainably produced base material.

Where possible we look to adopt materials that offer both sets of benefits – made from recycled and recyclable themselves too.

Eco-friendly Inks.

Eco from machinery to materials.

We have transitioned our printers to environmentally friendly Nordic Swan and Greenguard Gold certified inks because they do not emit VOCs (volatile organic compounds).

Our dye-sublimation lines also utilise environmentally friendly inks. Water-based and biodegradable is another way we print ‘green’.

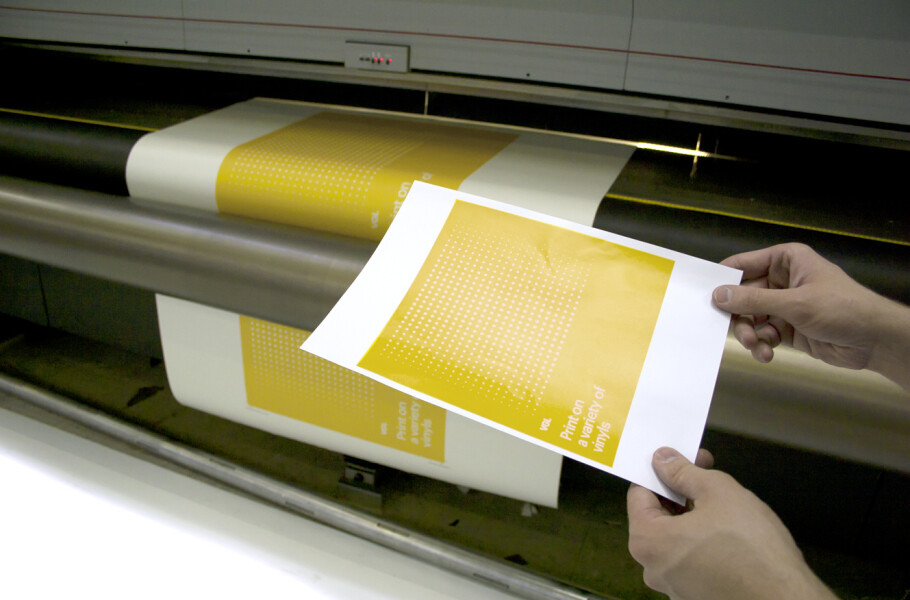

At the Forefront of Print Technology.

Leading the way.

We continually invest in our printing equipment to ensure we use the most effective and efficient print technology on every project, thereby reducing process waste and energy.

Our Mindful Footprint.

Sustainability in our daily lives.

Step by step we minimise our carbon footprint - something not only adhered to in our printing facilities. We have introduced energy efficient equipment and are transitioning to EV company vehicles.

We strive to lead by example, knowing that small changes will compound to deliver measurable results.

Contact Us.

Ready to get started? Get in contact with our knowledgeable staff who will be happy to assist.

0118 922 1300

[email protected]

268 Elgar Road South

Reading

Berkshire

RG2 0BT